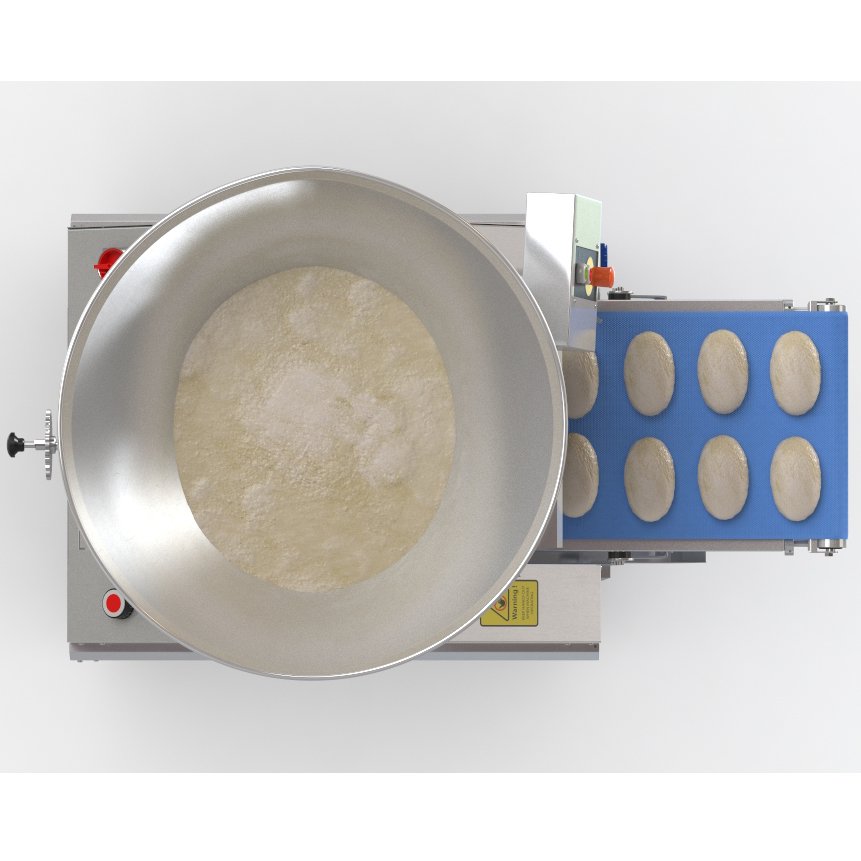

VOLUMETRIC DIVIDER

The dough dividing process is executed with precision by our volumetric divider machines, featuring a newly designed dividing drum and intake piston. This mechanism ensures proper division without causing damage or compression to even the most sensitive dough types. The construction of the dough hopper and outer lids is robust, made from stainless steel for durability.

The weight of divided dough can be configured either manually or through PLC control. Our volumetric divider is produced in distinct variations to accommodate different weight ranges: 2 oz – 7 oz, 4 oz – 21 oz, and 9 oz – 35 oz. The automatic machine (PLC controlled) divides a minimum of 20 and a maximum of 40 pieces per minute, while the manual machine achieves a range of 29 to 31 pieces per minute. Additionally, it boasts an impressive 80% reduction in oil consumption compared to other machines.

Technical Specifications of Manual Divider:

-Weight adjustment is manual, facilitated by flywheels located at the back.

-The main chassis is constructed from steel.

-Dividing drum is chrome-plated steel, and the piston chamber is stainless steel.

-Anti-corrosive piston.

-24V control board for efficient operation.

-Easy motion with a closed circuit lubrication system.

-When stopped, the piston consistently halts at the discharge position.

-Motor power transfer is achieved through a pulley and belt system.

-Standard hopper capacity is 154 lbs, with an optional 308 lbs hopper upon request.

-Covers are made of stainless steel.

-AC inverter is optional.

Technical Specifications of PLC Controlled Divider:

-Weight adjustment is done through the PLC-controlled touchscreen.

-AC inverter is standard for enhanced control.

-Dough twicing system is optional.

-Piece counter for accurate tracking.

-On/Off button for the flour duster.

-The main chassis is made of steel.

-Dividing drum is chrome-plated steel, and the piston chamber is stainless steel.

-Anti-corrosive piston.

-24V control board for efficiency.

-Easy motion with a closed circuit lubrication system.

-When stopped, the piston consistently halts at the discharge position.

-Motor power transfer is achieved through a pulley and belt system.

-Standard hopper capacity is 154 lbs, with an optional 308 lbs hopper upon request.

-Covers are made of stainless steel.

Single piston Volumetric Divider

| MODEL | DIMENSIONS W X D X H | CAPACITY | PISTON DIAMETER | DIVIDING RANGE | POWER | WEIGHT |

|---|---|---|---|---|---|---|

| BH-SPVD-M | 37" x 55" x 62 | 1200 - 2400 per hour | 3" | 2 oz - 7 oz | 208V - 3Ph 60Hz - 4AMPS | 992 lbs |

| 4" | 4 oz - 21 oz | |||||

| BH-SPVD- PLC (Control touch screen) | 5" | 9 oz - 35 oz |

Double piston Volumetric Divider

| MODEL | DIMENSIONS W X D X H | CAPACITY | PISTON DIAMETER | DIVIDING RANGE | POWER | WEIGHT |

|---|---|---|---|---|---|---|

| BH-DPVD-M | 39" x 56" x 69" | 2400 - 4800 per hour | 3" | 2 oz - 7 oz | 208V - 3Ph 60Hz - 5.7AMPS | 1543 lbs |

| BH-DPVD- PLC (Control touch screen) | 4" | 4 oz - 21 oz |